-

-

Call Us On

-

Mail Us @

ghp@gahhong.com

SAFETY CRITICAL

From design to manufacturing and quality control, we prioritise adherence to stringent safety standards and continuous improvement initiatives to ensure the utmost safety and reliability.

HIGHEST DURABILITY

Our products are renowned for their exceptional durability, ensuring reliable performance and longevity in even the most demanding applications.

UTMOST ROBUSTNESS

We exemplify the utmost robustness in our business approach, maintaining resilience across all operations, while upholding an unwavering commitment to precision, quality, and innovative excellence.

MAXIMISED SAFETY

Our products are meticulously crafted with a focus on maximised safety, ensuring the highest level of protection and peace of mind for our customers.

ENDURANCE TECHNOLOGY

We are equipped with state-of-the-art endurance technology, ensuring exceptional resilience and reliability even in the harshest conditions.

Superior Mechanical Engineering Skills

PROCESSABLE MATERIALS

Aluminum Alloys

2000-7000 series

Titanium Alloys

Grade 2

Grade 5 (Ti-6AI-4V)

Tool Steels

D2, H13, A2

P20, S7

Carbon and Alloy Steels

Mild steel (e.g., A36, 1018)

Medium & high carbon steels (e.g., 1045, 1095)

Alloy steels (e.g., 4140, 4340, 8620)

Stainless Steels

304, 316, 316L

410, 420

Duplex and Super Duplex

Copper Alloys

Pure copper

Brass (e.g., C36000)

Bronze (e.g., aluminum bronze)

Plastics and Polymers

POM (Delrin, acetal)

PTFE (Teflon)

Nylon, Polycarbonate, ABS

Nickel Alloys

Inconel (e.g., 718,625)

Monel (e.g., 400)

Hastelloy (e.g., C276)

Speciality Alloys

Magnesium alloys

Tungsten and Molybdenum alloys

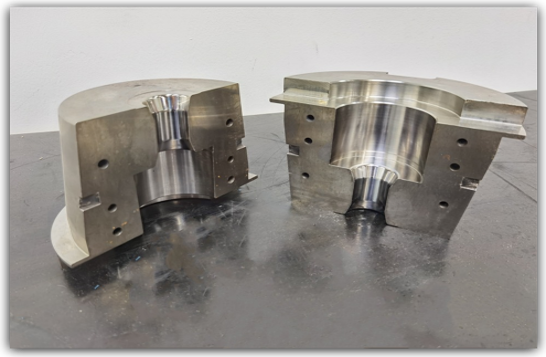

MANUFACTURING PROCESSES

- Plastic injection

- Casting

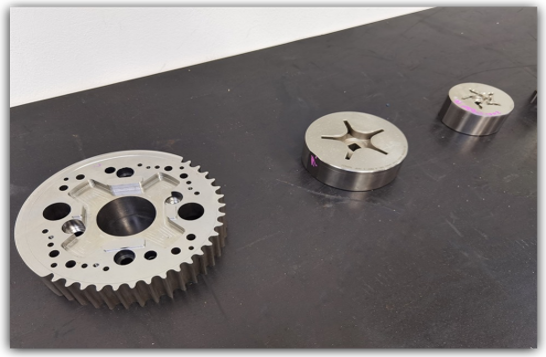

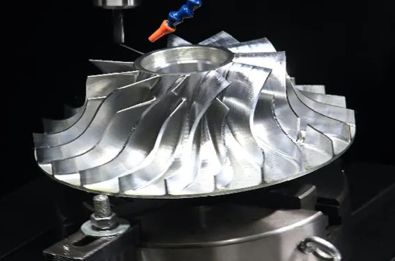

- 3-5 axis CNC milling and turning

- Wire-cut EDM

- Electrical discharge machining

- Grinding (profile & cylindrical)

SECONDARY FINISHING

- Surface enhancement & cleaning

- Non-destructive testing

- Chemical processing

- Painting

- Part marking

- Laboratory testing

- Heat treatment

APPLICATIONS

- Aerospace components

- Machine mechanical components

- Gears

- Magnetic plates

- Shafts

- Custom screws

Markets and Products

OEM

SEMICONDUCTOR

AEROSPACE

SPORTS

NEW ENERGY